Groundbreaking pilot project using smart2i

WIN woodworking INTERNATIONAL, 2025.1, S. 20-21

Hesse Lignal, a specialist in intelligent and sustainable coating solutions for trade and industry, was faced with the same production optimization challenges as its own customers. The coating manufacturer was looking for a holistic solution. Dirk Conrad, Head of Application Technology at Hesse Lignal, reports on his positive experiences with the Industry Intelligence solution smart2i of Hymmen.

A continuous and trouble-free production flow is the goal of every manufacturing company. It should be ensured by means of successful process management and quality monitoring.

Companies face multiple challenges in this regard - not just when it comes to finishing their surfaces: it starts with the surface complexity caused by product diversity, continues with the piecemeal addition of production lines and the lack of data transparency and ends with the cross-industry shortage of skilled workers and the social goal of sustainable production. To date, there has been no holistic approach to meeting all challenges simultaneously.

This gave rise to the idea of a pilot project to test the new smart2i industrial software solution of long-standing technology partner Hymmen.

“I can take the result straight away,” reports Dirk Conrad enthusiastically. “Transparency in production significantly increases product quality and the overall result!”

smart2i enables the digital transformation of production processes. All data generated by the machines is recorded automatically. This prevents error-prone and inaccurate manual recordings of quantities. Temperatures, pressures, quantities and many other process-data are recorded digitally. This enables production managers to analyze the most frequent reasons for failure on a data basis down to the second. So, they can understand their systems in detail and determine preventative measures. Rejections have been reduced, and no new quality problems have arisen in production.

Dirk Conrad was particularly impressed by the following product features:

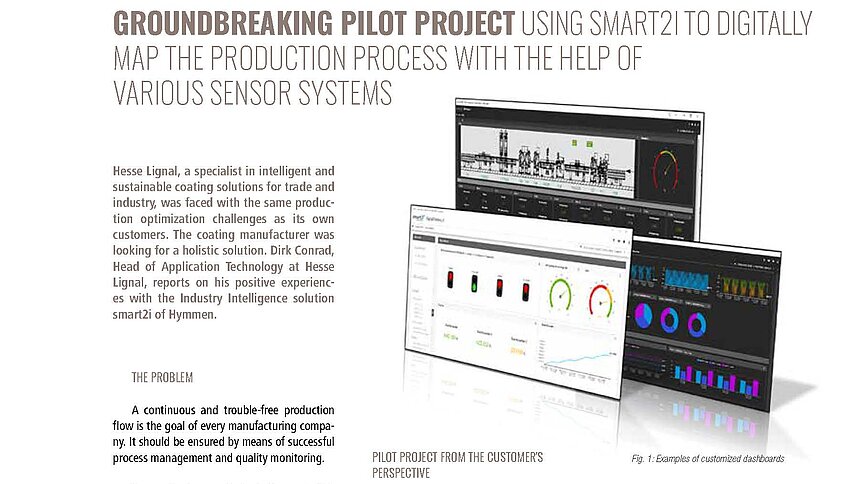

- Customizable dashboards

- All sources combined in one system

- Combination of machine and quality data

- Accessible from PC, tablet or smartphone

Machines and sensors are connected via the smart2i-connect gateway (see Fig. 1). The recorded data can be analyzed to the second. This greatly simplifies both the calibration of the overall process and subsequent production operations.

Hesse has now extensively tested the Industry Intelligence solution in its in-house technology center and applied it to a wide range of customer processes. Not only the promised increase in production is convincing, but also the avoidance of waste and the reduction of the reject rate by up to 12%. Above all the simple handling of the system stands out. All data and information are visualized at the touch of one single button. “We can only recommend smart2i,” summarizes Dirk Conrad. “It is a comprehensive system that can be used for any type of plant configuration.”