Applications

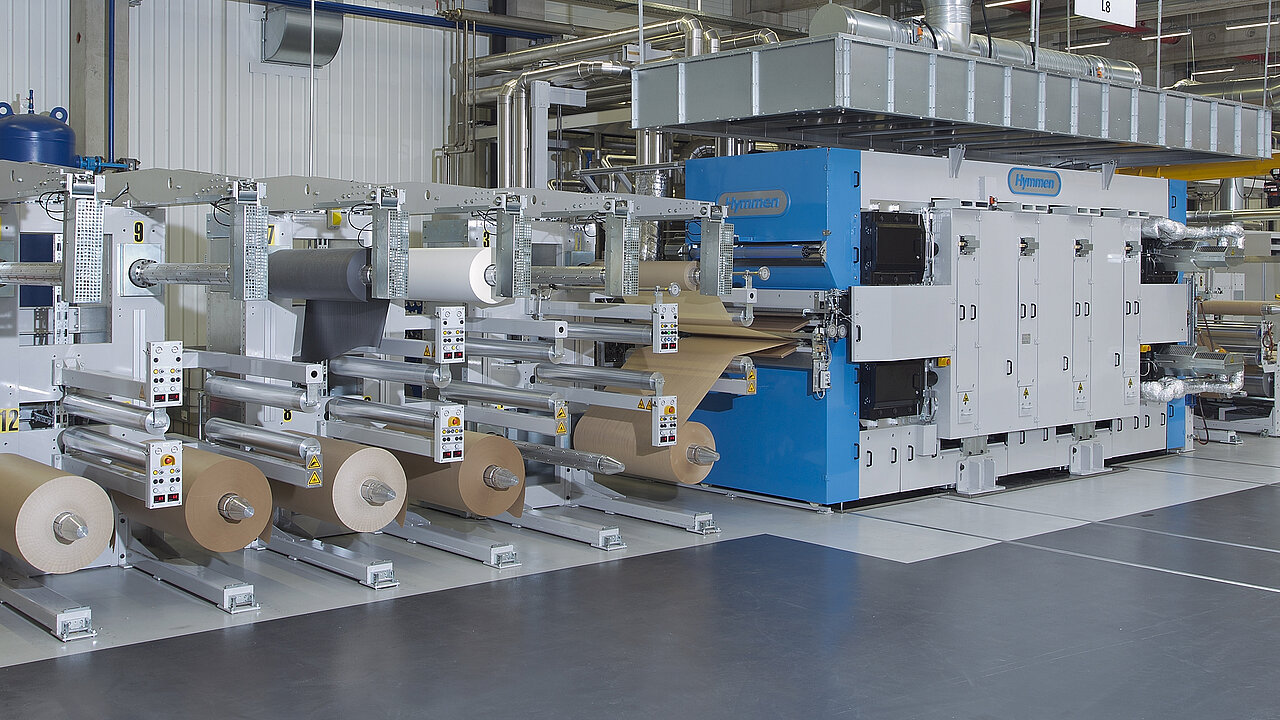

Hymmen double belt presses offer versatile solutions for processing roll goods, sheet materials, and panel products. Typical applications include

- decorative laminates

- laminate flooring

- melamine boards

- kitchen worktops

Technically always one step ahead

We are committed to delivering exceptional technological support by anticipating our customers' needs and collaborating closely with them. Through continuous innovation, we help enhance and streamline their production processes.

Solid base of process expertise

Our deep understanding of our customers’ production processes extends beyond machinery. With expertise in materials, substrates, and workflows, we provide the context needed to deliver tailored, solution-oriented technologies.

Hymmen as established system partner

With decades of expertise in mechanical and plant engineering, Hymmen supports you from process development through to commissioning—and beyond, throughout the plant’s lifecycle.

Your Advantages

- High economic efficiency: savings in material, energy and labor costs

- Reproducible high quality thanks to uniform pressure and constant temperature

- Low production costs due to high capacities and high productivity

- Highly efficient thanks to short set-up times and continuous processes

- Space-saving system layout

Technical Highlights

- Press pressure up to 70 bar

- Microlaminates and variable product thicknesses without set-up time

- Heating and cooling without pressure interruption

- Minimal press belt change times

- Temperature up to 250° C

- Press widths 700 - 2,500 mm

- Print zone length 2,000 - 6,000 mm

- Speed 1 - 45 m/min

- Inline process with minimal process tolerances