Applications

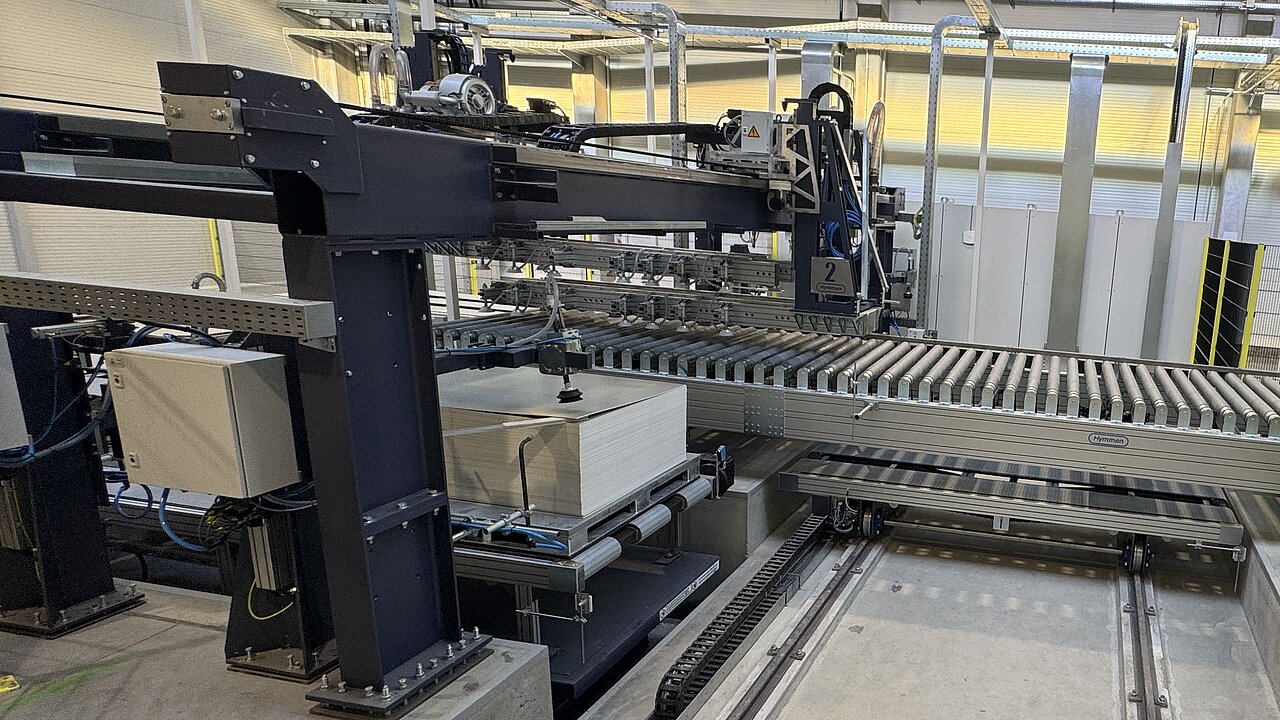

Our tandem gantries for feeding and stacking meet the high capacity requirements of flooring production. If digital printing on furniture panels or flooring has to be very precise, our high-precision transport systems are in demand. And for high-gloss or super matt finishing, we offer suitable in-line processes for edge processing, gentle transportation and sealing of the high-quality surfaces.

learn more

Technically always one step ahead

We are committed to delivering exceptional technological support by anticipating our customers' needs and collaborating closely with them. Through continuous innovation, we help enhance and streamline their production processes.

Solid base of process expertise

Our deep understanding of our customers’ production processes extends beyond machinery. With expertise in materials, substrates, and workflows, we provide the context needed to deliver tailored, solution-oriented technologies.

Hymmen as established system partner

With decades of expertise in mechanical and plant engineering, Hymmen supports you from process development through to commissioning—and beyond, throughout the plant’s lifecycle.

Your Advantages

- Customized handling solutions even for confined hall architecture

- Process experience from more than 130 years of mechanical engineering ensures the selection of the right handling and processing solutions

- Integration of process control along the entire production process

- Validation of complex processes via simulations with the help of the digital twin

Technical Highlights

- Solutions for demanding tasks such as high-precision transport in digital printing

- Fulfillment of high cycle outputs with complex handling requirements

- Precise gap control in processes thanks to special process automation

- In-house robot programming, even for synchronous-continuous movements