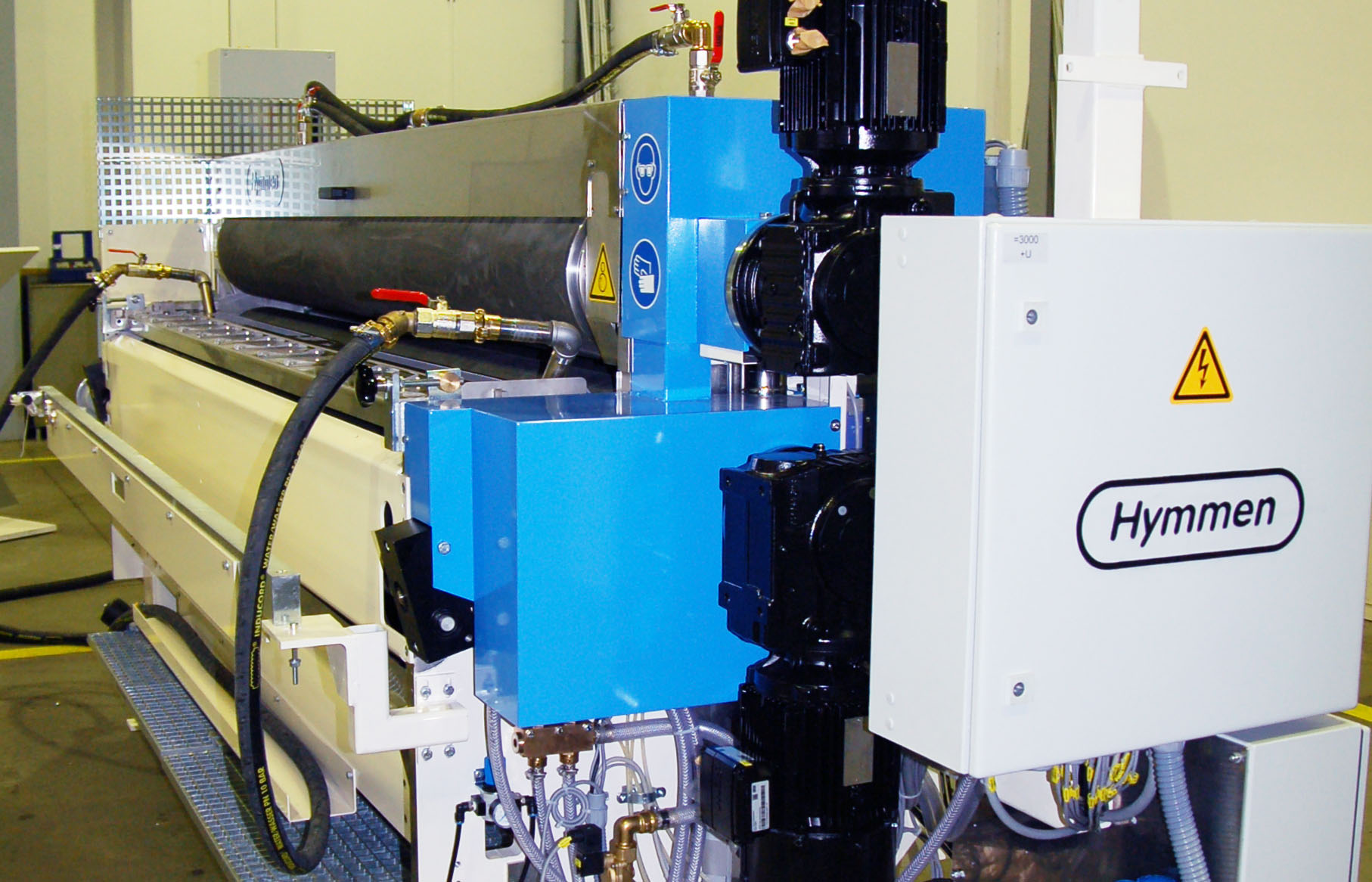

Laminating Lines and Glue Application Machines: Modular Design – Top Performance

Hymmen laminating and glueing lines have enjoyed global renown in the board and furniture industry for decades. They have won praise for their innovation, quality and performance when it comes to protecting materials, decor application and the addition of favourable material characteristics. Worldwide, some 200 Hymmen laminating lines are currently in operation in a range of versions that cover a huge spectrum of technical options.

Outstanding surface quality

High lamination repeat accuracy thanks to special camera and control systems using register marks

Rapid foil change

Automatic foil splicing during foil roll change

Minimum foil wastage thanks to high-precision gap control and the highly dynamic cutting system for board separation

Application method

Slotted nozzle (papers or foils from 23 g/m2)

Roller application (panel material)

Today's furniture industry is dominated by modern prepreg-based finishing foils with increasingly superior surface characteristics and structures and thermoplastic decoration foils, e.g. for attractive high-gloss surfaces.

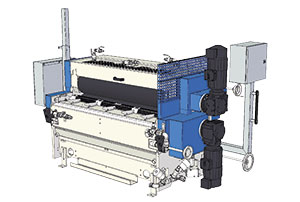

![[Translate to Englisch:] Kaschieranlagen Maschine CTK von Hymmen Maschinenbau & Anlagenbau [Translate to Englisch:] Kaschieranlagen Maschine CTK von Hymmen Maschinenbau & Anlagenbau](/fileadmin/user_upload/Slider_Produkte/produkte-kaschieranlagen-maschine-ctk-300x202.jpg)

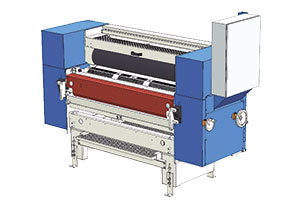

![[Translate to Englisch:] Kaschieranlagen Maschine KSA von Hymmen Maschinenbau & Anlagenbau [Translate to Englisch:] Kaschieranlagen Maschine KSA von Hymmen Maschinenbau & Anlagenbau](/fileadmin/user_upload/Slider_Produkte/produkte-kaschieranlagen-maschine-ksa-gummikalander-fuer-sonderfolien-300x202.jpg)

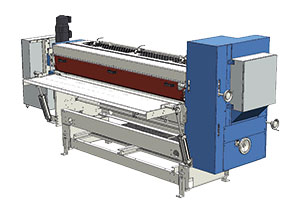

![[Translate to Englisch:] Kaschieranlagen Maschine KSA mit Schlitzdüse [Translate to Englisch:] Kaschieranlagen Maschine KSA mit Schlitzdüse](/fileadmin/user_upload/Slider_Produkte/produkte-kaschieranlagen-maschine-ksa-mit-schlitzduesen-300x202.jpg)

![[Translate to Englisch:] Kante kaschiert durch hymmen Kaschieranlage [Translate to Englisch:] Kante kaschiert durch hymmen Kaschieranlage](/fileadmin/user_upload/Inhaltsbilder/produkte-kaschieranlagen-produktbeispiele-kaschierte-kante-638x542.jpg)

![[Translate to Englisch:] Möbelplatten kaschiert duch Hymmen Kaschieranlage [Translate to Englisch:] Möbelplatten kaschiert duch Hymmen Kaschieranlage](/fileadmin/user_upload/Inhaltsbilder/produkte-kaschieranlagen-produktbeispiele-moebelplatten-kaschiert-638x542.jpg)

![[Translate to Englisch:] Strukturfolie auf MDF-Platte hergestellt durch Hymmen Kaschieranlagen [Translate to Englisch:] Strukturfolie auf MDF-Platte hergestellt durch Hymmen Kaschieranlagen](/fileadmin/user_upload/Inhaltsbilder/produkte-kaschieranlagen-produktbeispiele-strukturfolie-auf-mdf-platte-638x542.jpg)

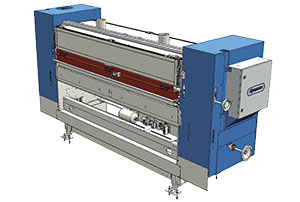

![[Translate to Englisch:] Hymmen FLK Kaschieranlage [Translate to Englisch:] Hymmen FLK Kaschieranlage](/fileadmin/user_upload/Slider_Produkte/produkte-kaschieranlagen-maschinen-flk-300x202.png)

![[Translate to Englisch:] FKA Kaschieranlage von Hymmen [Translate to Englisch:] FKA Kaschieranlage von Hymmen](/fileadmin/user_upload/Slider_Produkte/produkte-kaschieranlagen-maschinen-fka-300x202.png)

![[Translate to Englisch:] CTK Kaschieranlage von Hymmen [Translate to Englisch:] CTK Kaschieranlage von Hymmen](/fileadmin/user_upload/Slider_Produkte/produkte-kaschieranlagen-maschinen-ctk-300x202.png)